QUIRK WIRE SERVICES

Bonding

Quirk Wire bonding uses a silica material with PTFE added to the solution. A granular surface is actually bonded to the wire insulation to mechanically aid in encapsulation.

Etching

Quirk Wire sodium naphthalene based etchants are much more aggressive than bonding and will physically allow wire to be held tighter in the encapsulation process. The special cleaning process used on our etched wire insures a surface free of build-up.

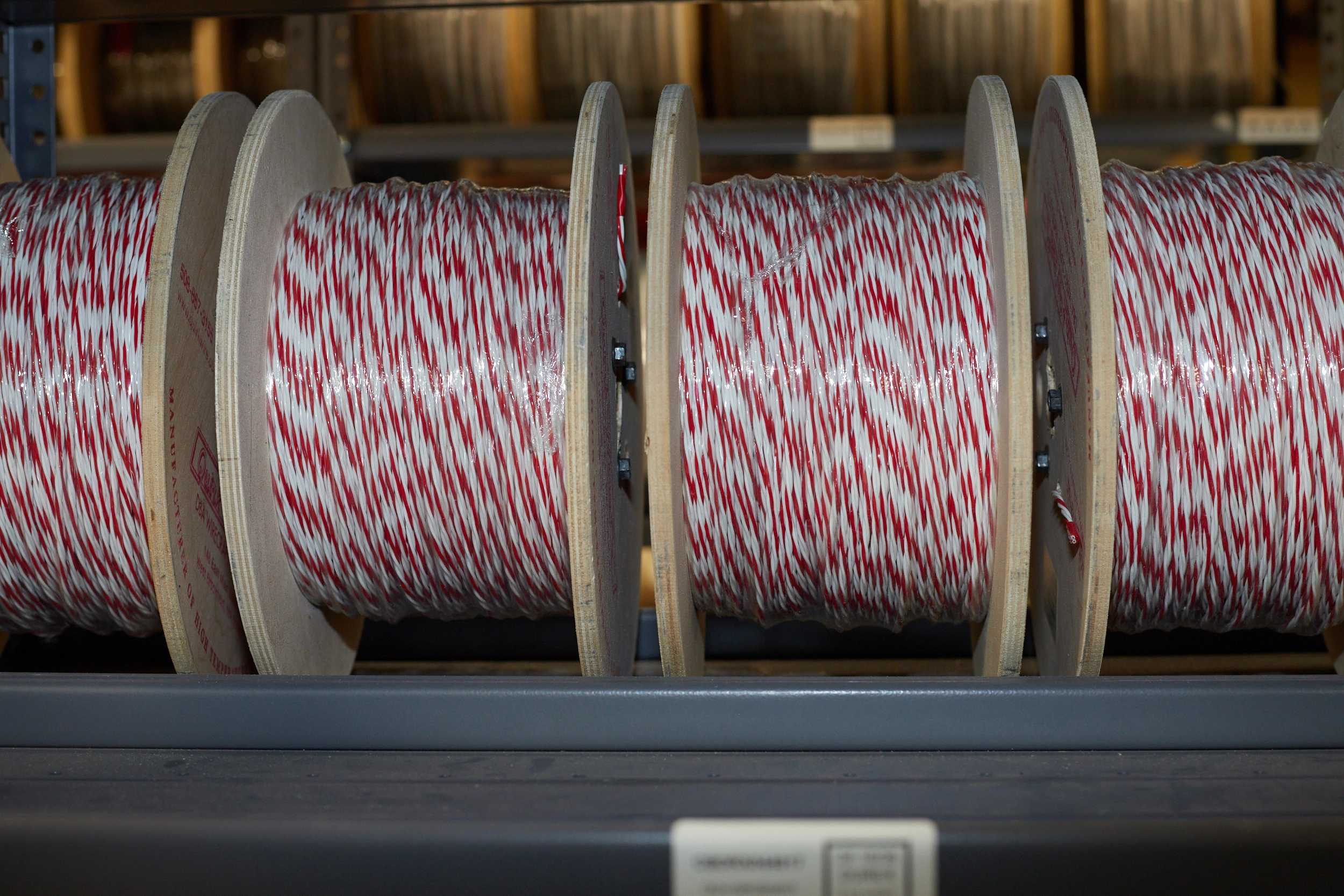

Printing

Quirk Wire prints hook-up wire to meet UL, CSA, and military specifications. We will also print special legends on hook-up wire and on some jackets per customer requirements.

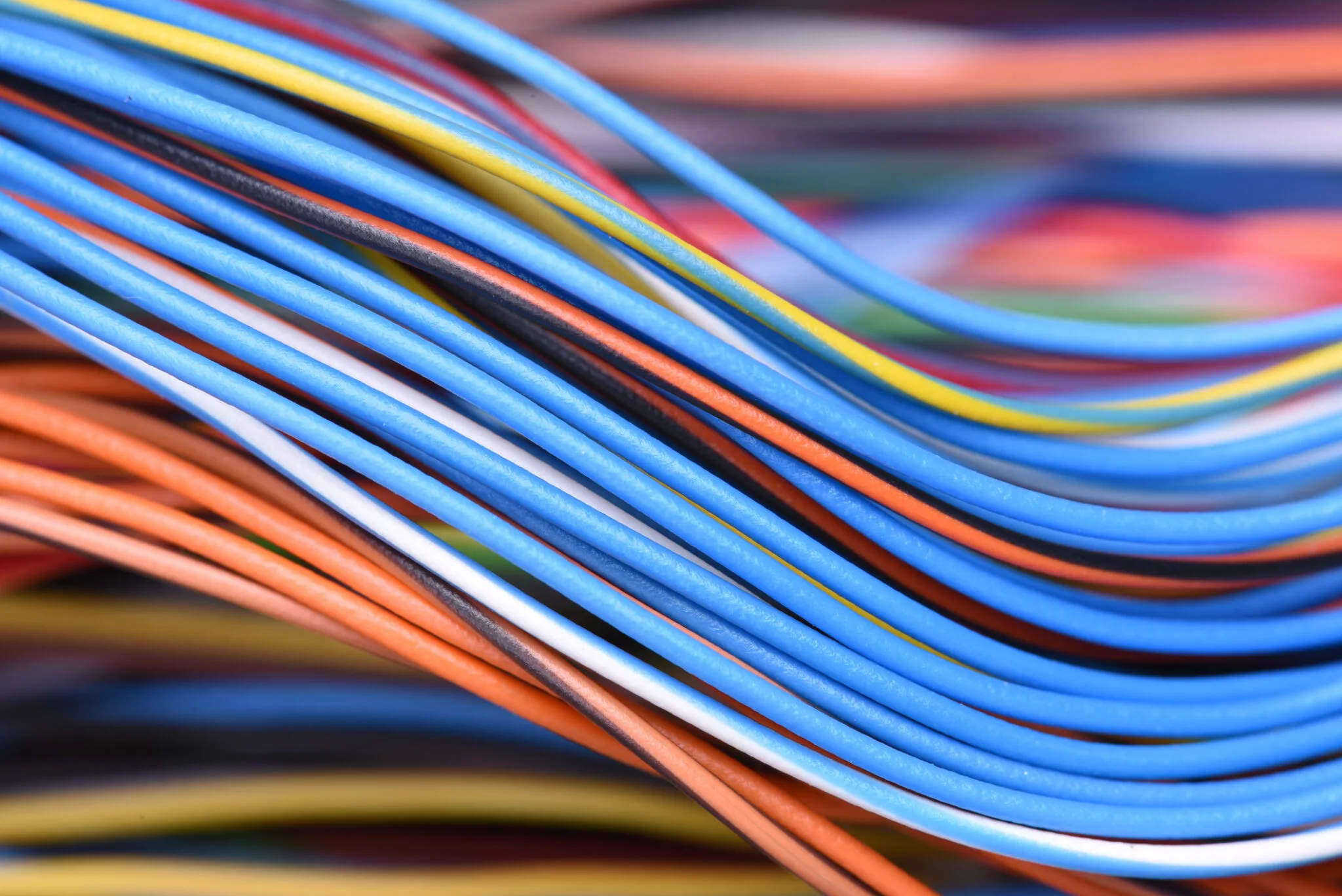

Striping

Quirk Wire can stripe 30 awg. through 10 awg.

Special OD's

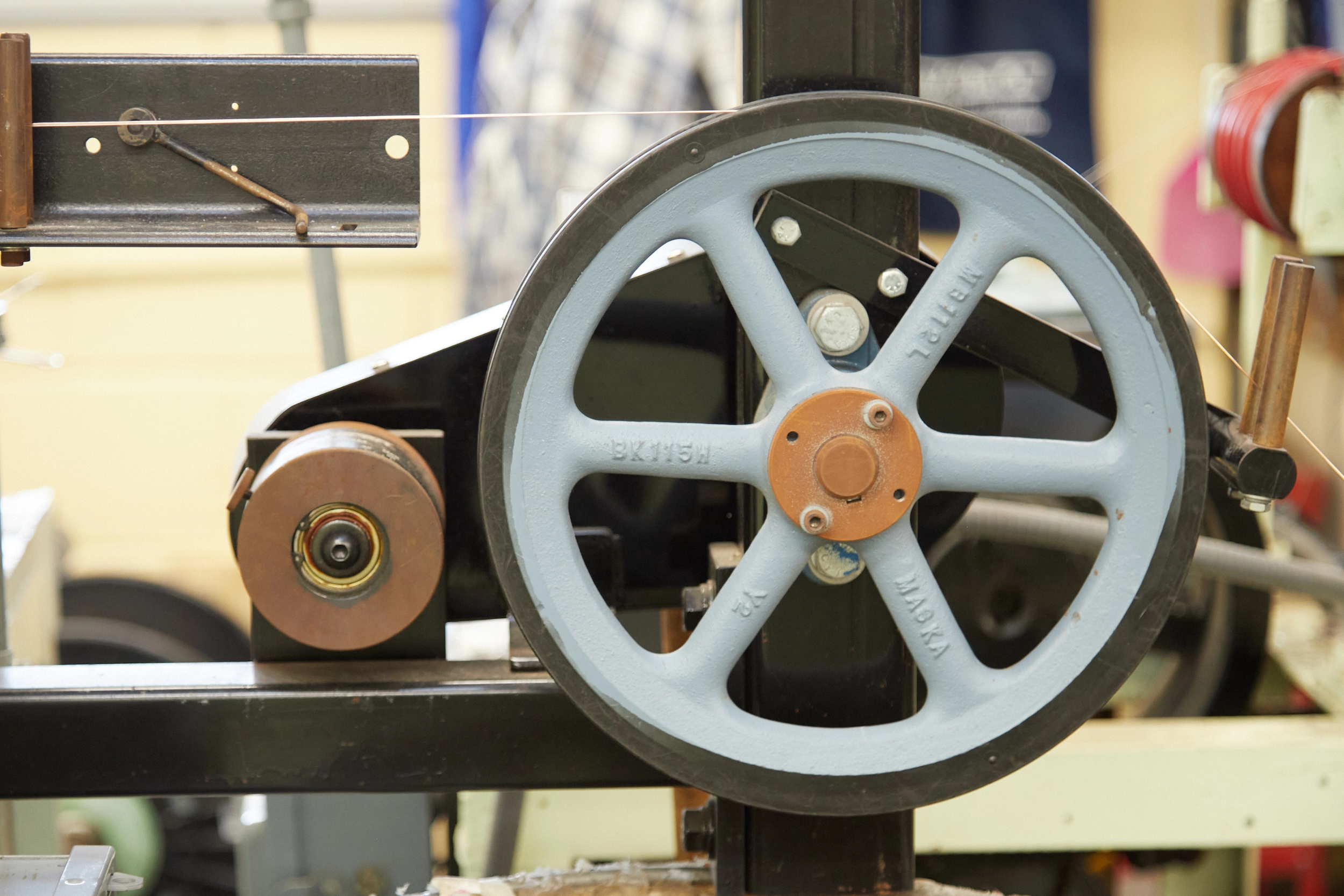

Quirk Wire will manufacture special outside diameters which may be requested for extruded, wrapped, or jacketed wire and cable.

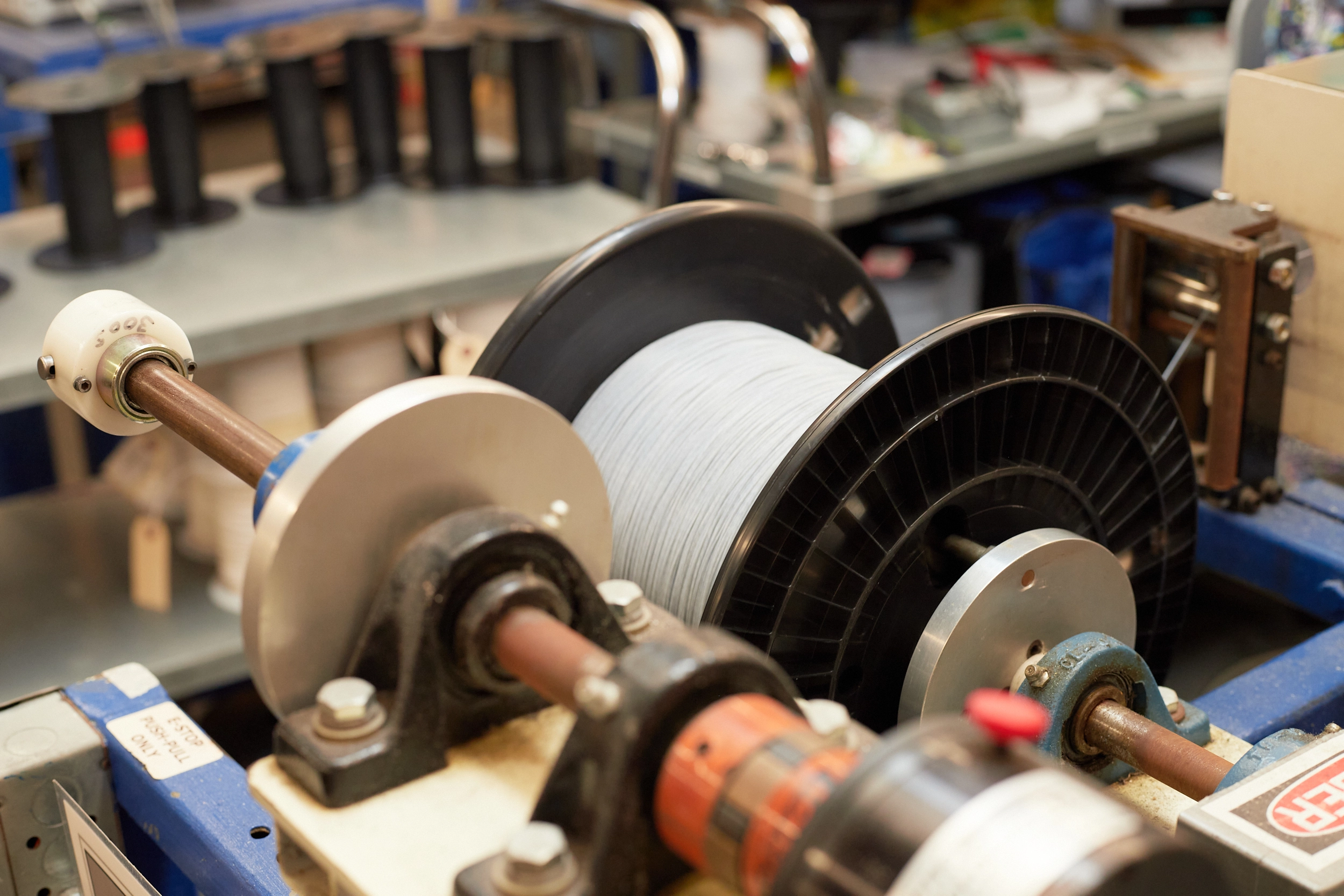

Matched Multiples

Quirk Wire can ship wire and cable in exact matched multiples for cabling, harnessing, or further processing when a minimum amount of scrap is needed.

Special Constructions

Quirk Wire operates as a job shop to manufacture high temperature wire and cable. Within existing specifications we can custom design new products for specific applications using many conductors, dimensions, and insulations which may not be shown on this website.